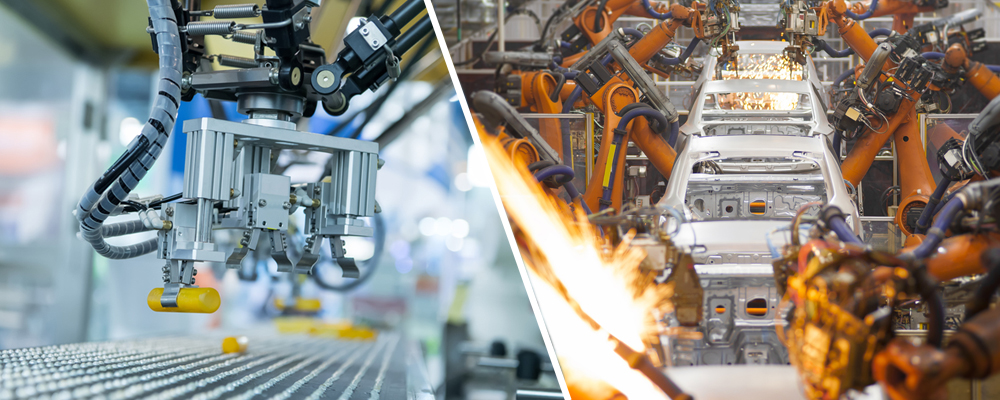

As we are living in highly competitive business environment, the industry or in other words manufacturers is challenged by the factors like withstand to harsh manufacturing environments, meeting latest energy efficient standards and to offer a robust level of security, etc. And, above all, the rapid advancement of technology usage in all industrial sector is implanting immense pressure on manufacturing, industrial processing systems, factories, machinery, test facilities, etc., which is turning them from mechanization to automation. As new and efficient control technologies evolve, computerized automation control is being driven by the need for high accuracy, quality, precision and performance of industrial processes. Hence, we have developed Automation itself as a separate business vertical, a step beyond the mechanization - which provides advance services to make use of high control capability devices for an efficient manufacturing and production processes.

Our team is well versed with mechanization - a system which needs human intervention to operate the manual operated machinery, and to change the system to Automation - a system which is the technology by which a process or a procedure is performed without human assistance. Our team has gained immense expertise in automation and automatic control along with the use of various control systems for operating equipment, such as machinery, processes in factories, boilers and heat-treating ovens, switching on telephone networks, steering and stabilization of ships, aircraft and other applications and vehicles with minimal or reduced human intervention.

Our industrial automation services team offers the use of control devices such as PC/PLCs/PACs etc. to control industrial processes and machinery by replacing as much possible labour intervention and dangerous assembly operations with automated ones. We have gained industrial control knowledge for wide number of process variables such as temperature, flow, pressure, distance, and liquid levels to sense simultaneously, which can be acquired, processed and controlled by complex microprocessor systems or PC based data processing controllers.

Our control system team is well versed with the various types of closed loop control techniques which ensure the process variables to follow the set points. In addition to this basic function, the team is also well versed with automation system’s other functions such as computing set points for control systems, plant start up or shut down, monitoring system performance, equipment scheduling, etc. along with the control systems along with monitoring adapted to the operating environment in an industry for flexible, efficient and reliable production system.

Some of the following are the reasons why use our services:

- To Increase the Labor Productivity

- To improve the Product Quality

- To Reduce the Labor or Production Cost

- To Reduce Routine Manual Tasks

- To Improve Safety

- To Assist Remote Monitoring

Our vendor-neutral Industrial Automation and Control Solutions are used by clients in the manufacturing industry to gain access to real-time data and insights. The solution is backed by our extensive experience in automation platforms across the business and plant layer. It is designed to orchestrate physical and digital business process with a high degree of visibility.